University of Pennsylvania |Fall 2023 | Instructor: Dr. Masoud Akbarzadeh

This research introduces a novel approach to floor system design, leveraging sheet-based polyhedra structures and advanced digital fabrication techniques. Central to this research is the exploration of polyhedral geometries applied to sheet materials, aiming to create strong, lightweight floor systems with aesthetic value. A significant portion of the study involves the development and implementation of Python code for robot CNC milling, which facilitates precise and efficient material processing. Additionally, custom Grasshopper components were designed to streamline the design process, enabling rapid prototyping and optimization of polyhedral forms. Through computational simulation and analysis, the structural integrity and practical viability of these systems were rigorously evaluated. The paper discusses the intersection of architectural innovation, computational design, and sustainability, highlighting how these digitally-driven methods can transform the fabrication and design of modern architectural elements. The results underscore the effectiveness of integrating sheet-based polyhedra with cutting-edge digital fabrication techniques, promising enhanced efficiency, sustainability, and adaptability in building design.

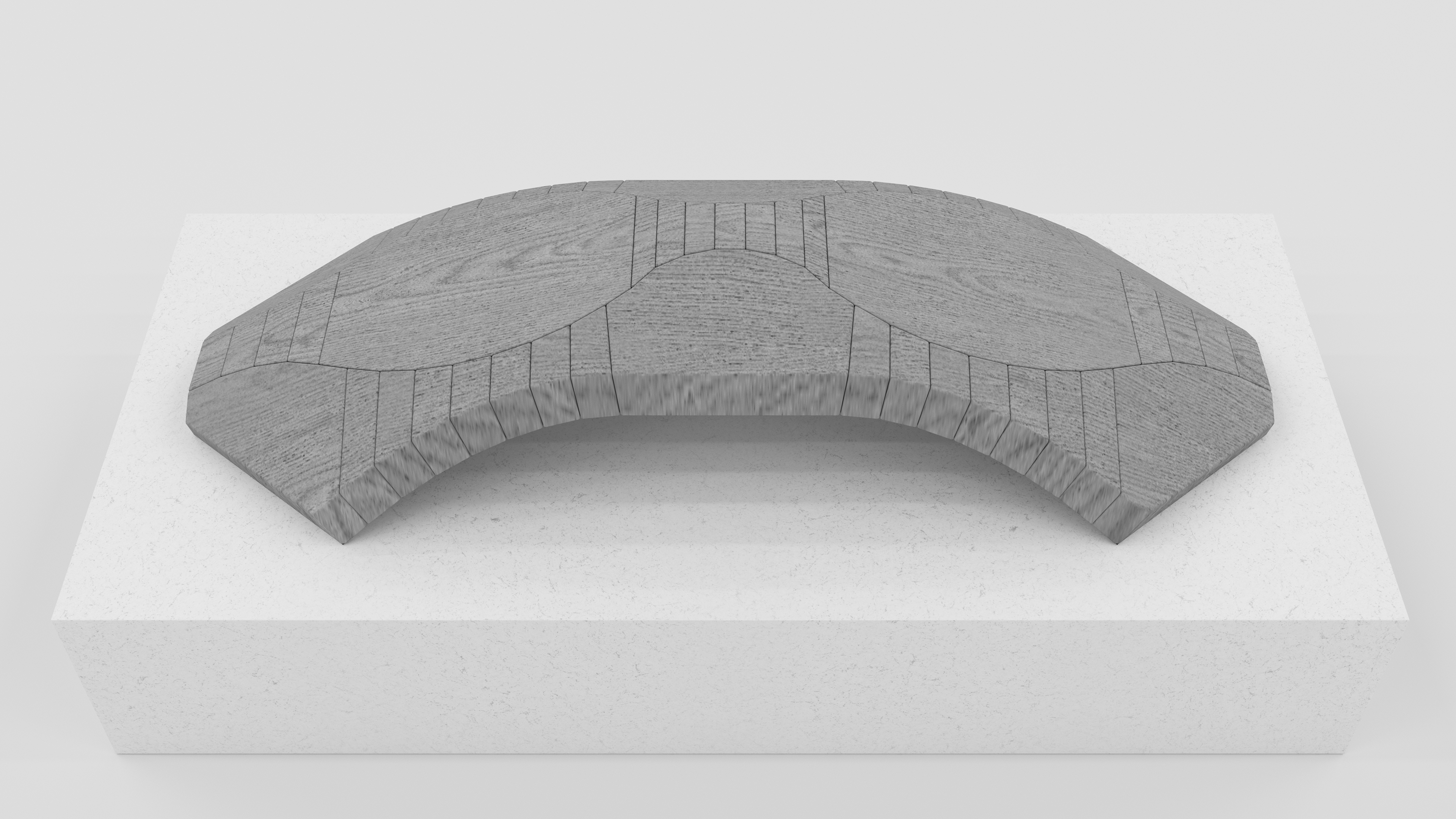

General Four-Point-Support Graphic Static Pattern

A subdivision strategy is used to generate or approximate curves in a graphical static structure. This technique involves dividing the curve into smaller, manageable line segments that can be easily analyzed and represented. Each segment is treated as a linear or slightly curved element, thus simplifying the overall complexity of the structure. By progressively refining these line segments, the subdivision method allows for a more accurate approximation of the original curve.

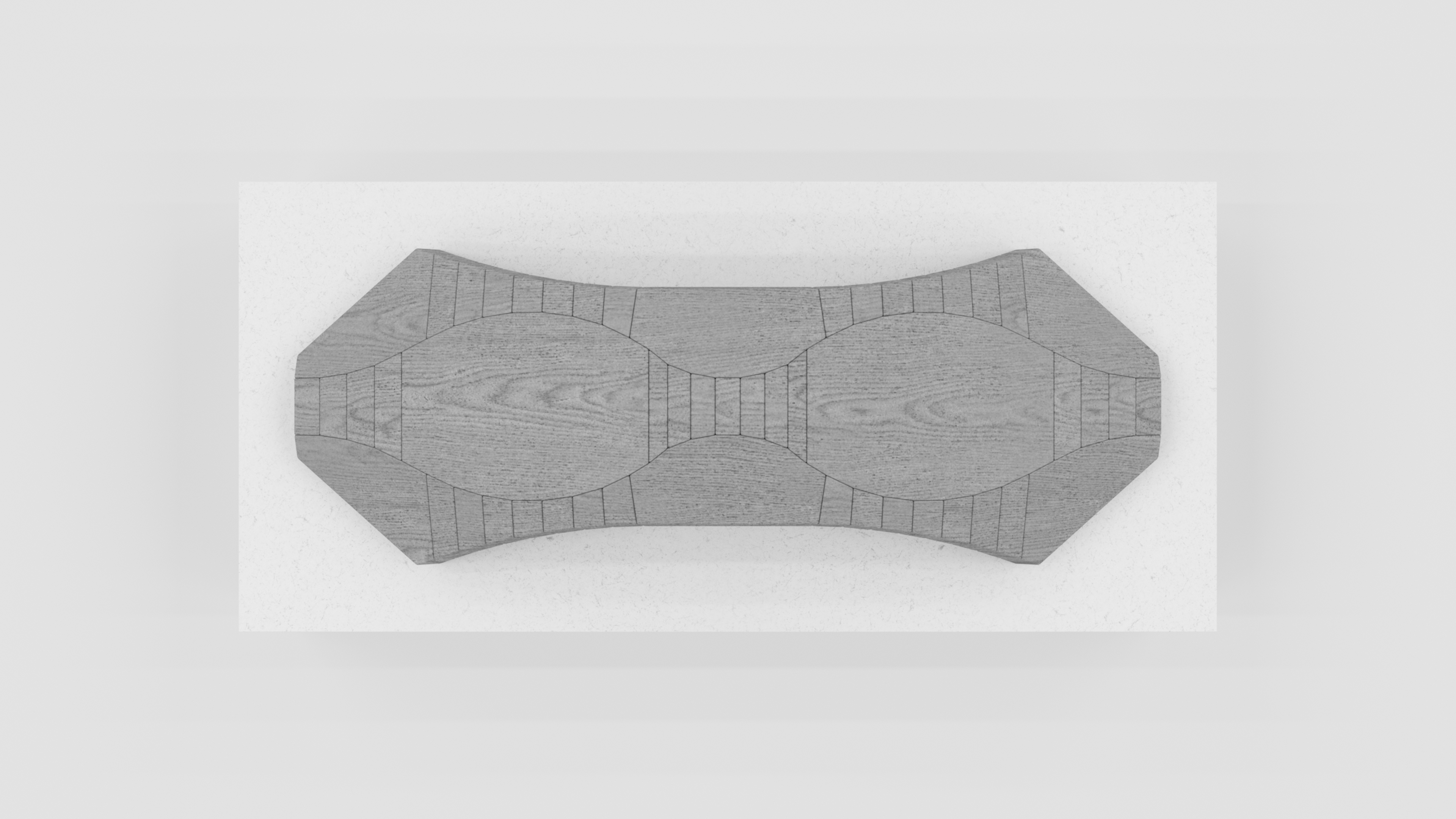

Duplicated Graphic Static Structure Pattern

A fascinating approach to creating larger and more complex designs by repeating or collaging simple “Curved” graphic static structures. This approach involves taking typical and arranging them in different orientations to produce basic graphic static structures. By rotating them, they create complex structural forms. This repetition and variation enhances the aesthetics.

Typical Grid w/ Average Load Distribution

The process of forming larger, more complex designs by repeating or collaging simple “curved” graphic static structures is guided by a matrix of 0 and 1 that serves as a blueprint for determining the direction of typical patterns. Each element of the matrix represents a decision point: the 0 and 1 represent the two directions of a typical pattern: horizontal and vertical. By manipulating this matrix, the designer can create a variety of styles within the realm of graphic static structures. A systematic and creative exploration of structural possibilities is made possible by this approach. Using the binary matrix in this way not only simplifies the decision-making process but also opens up a world of geometric and aesthetic possibilities, with each combination yielding a unique structural expression.

When designing a graphic static floor structure, it is necessary to consider the distribution load and how it changes from a uniform distribution load area to a UNEVEN distribution load area. This change allows the floor structure to determine the structure form based on the size and location of the load.

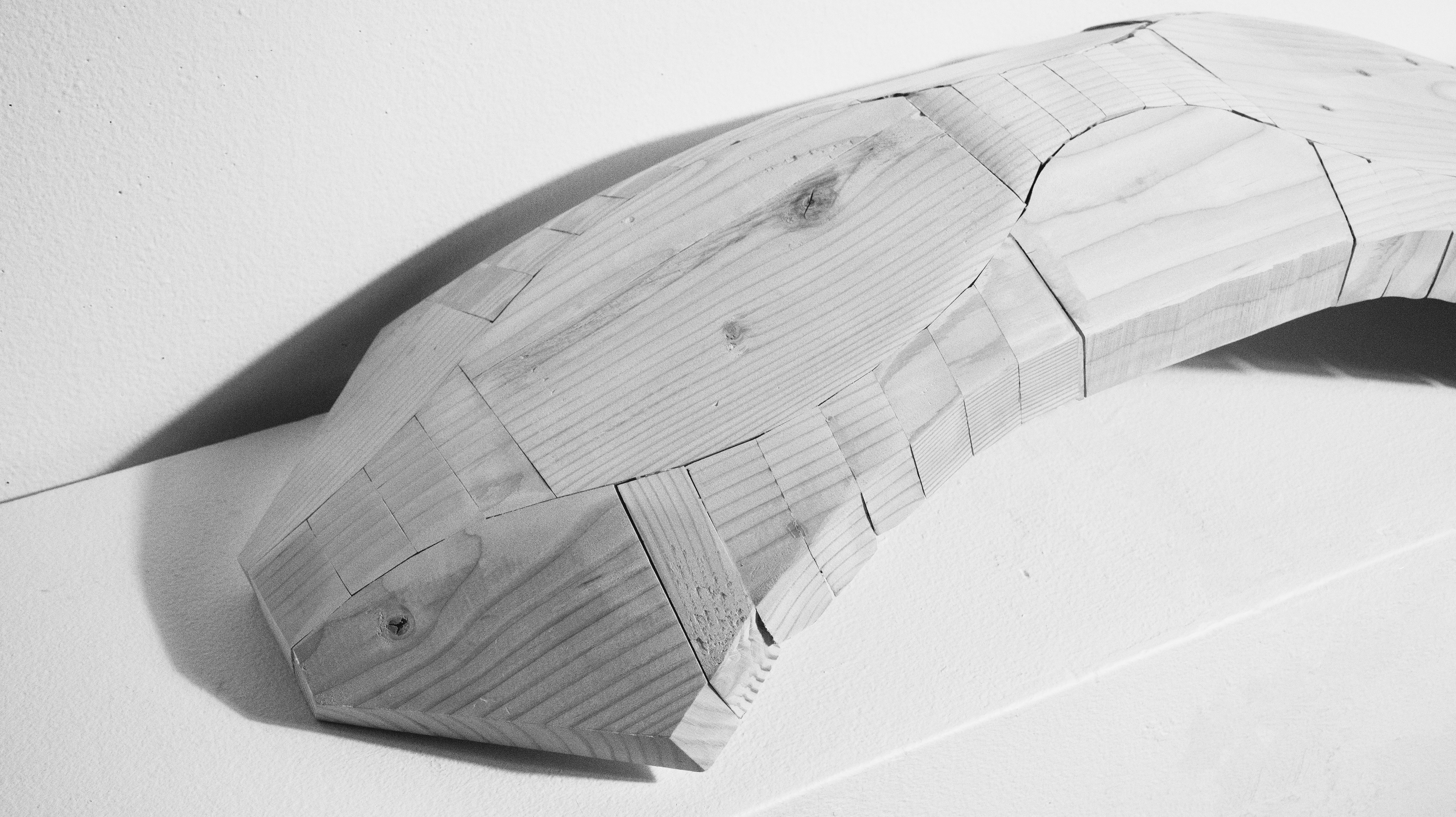

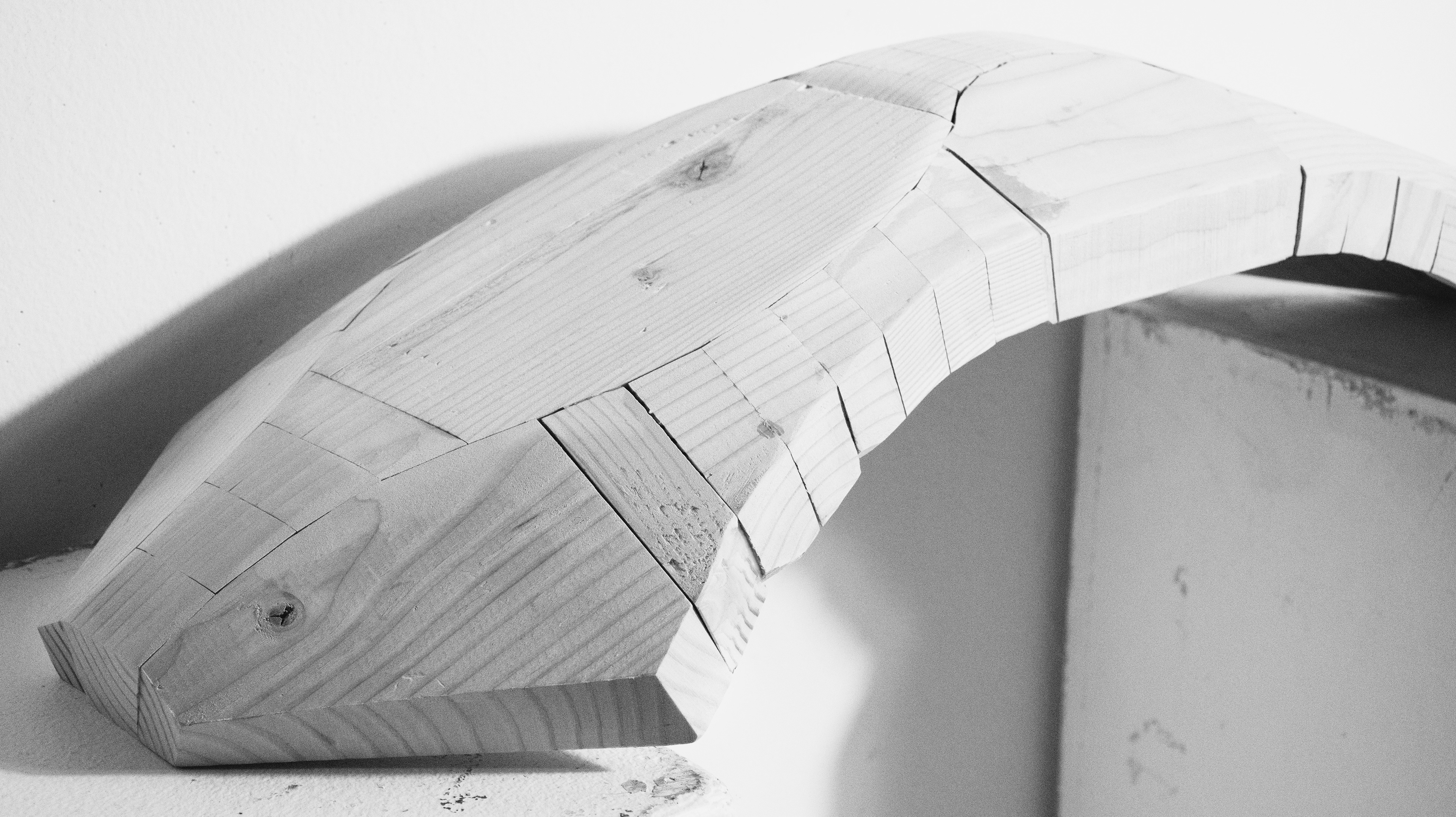

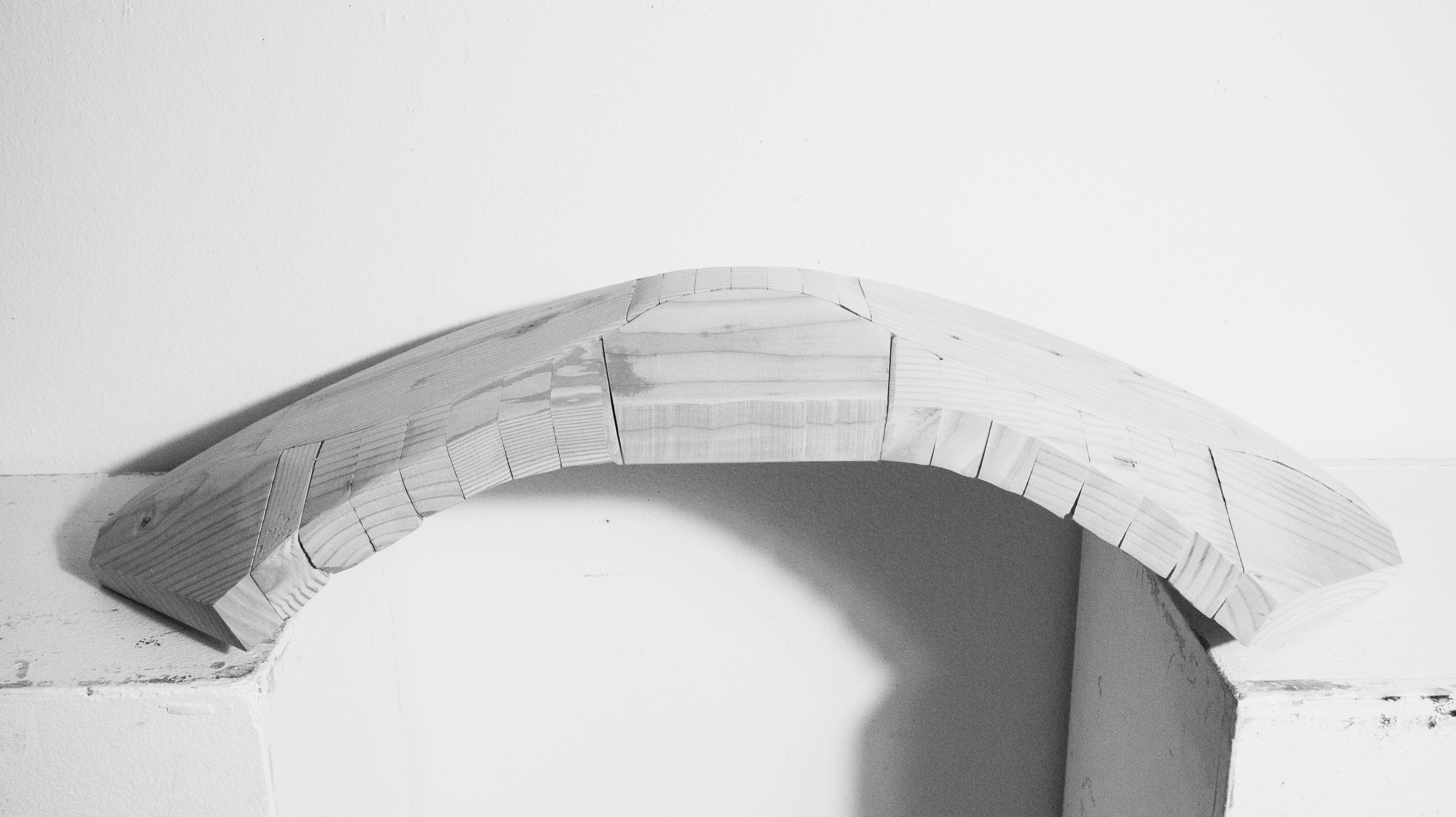

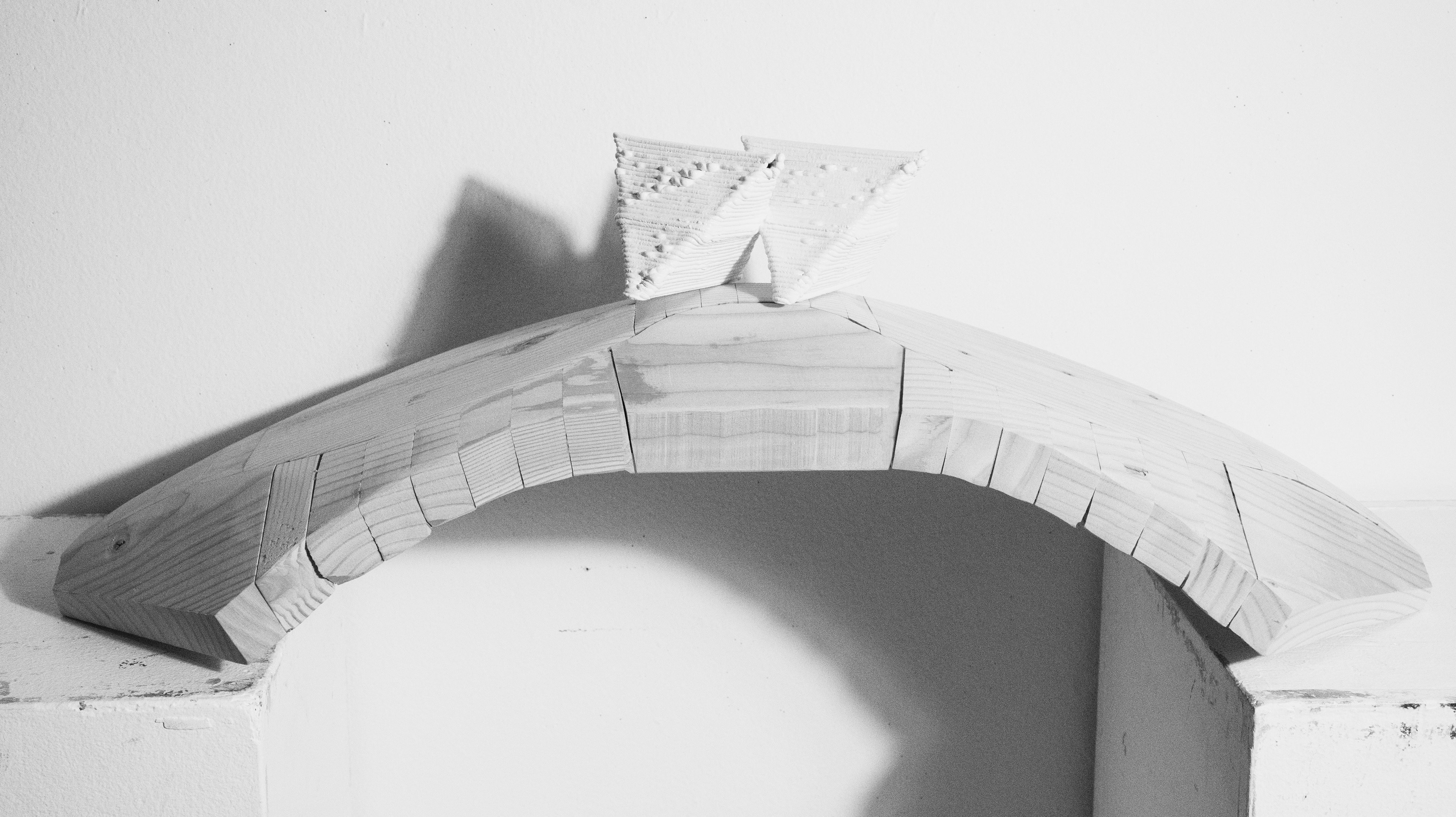

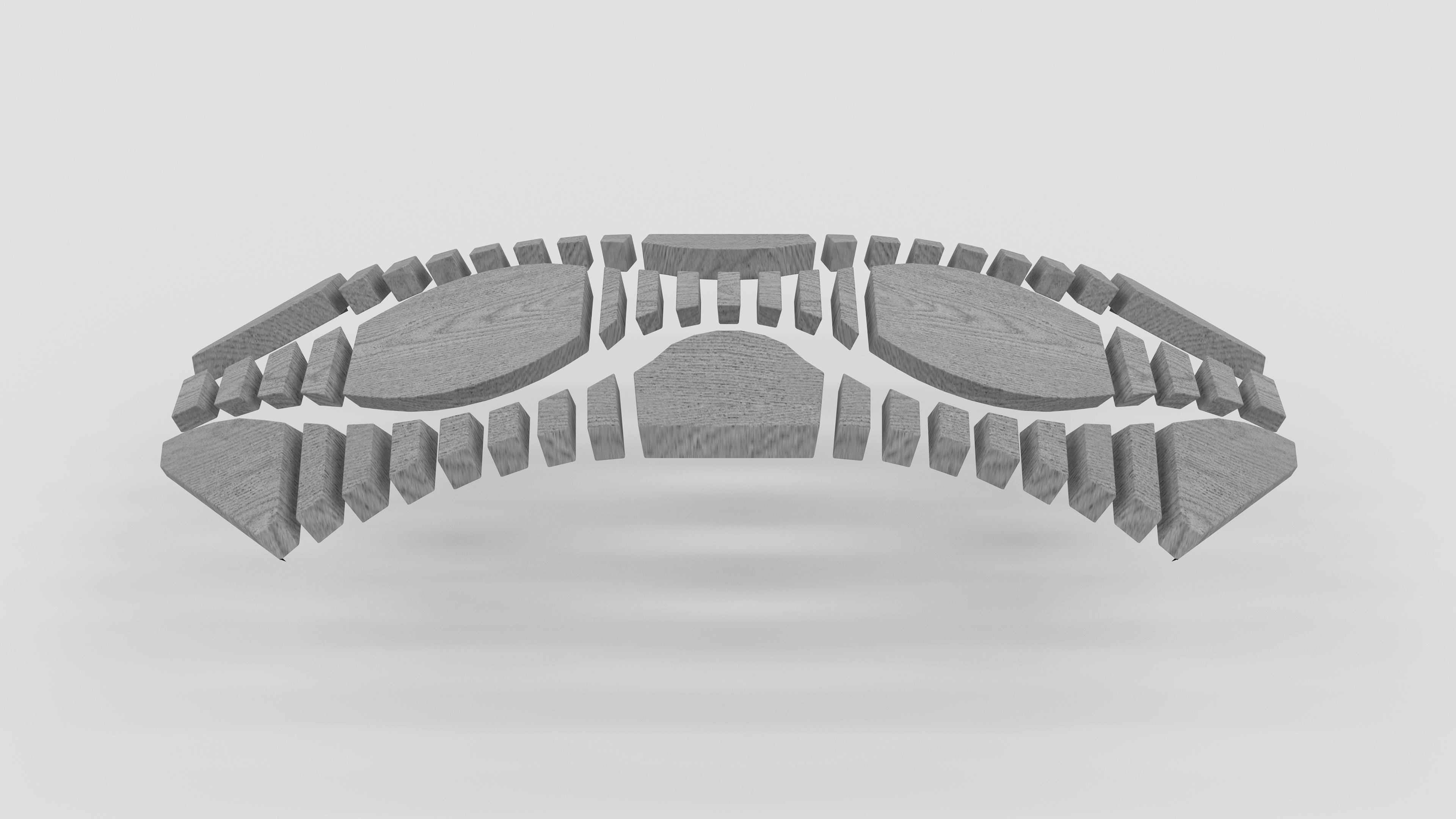

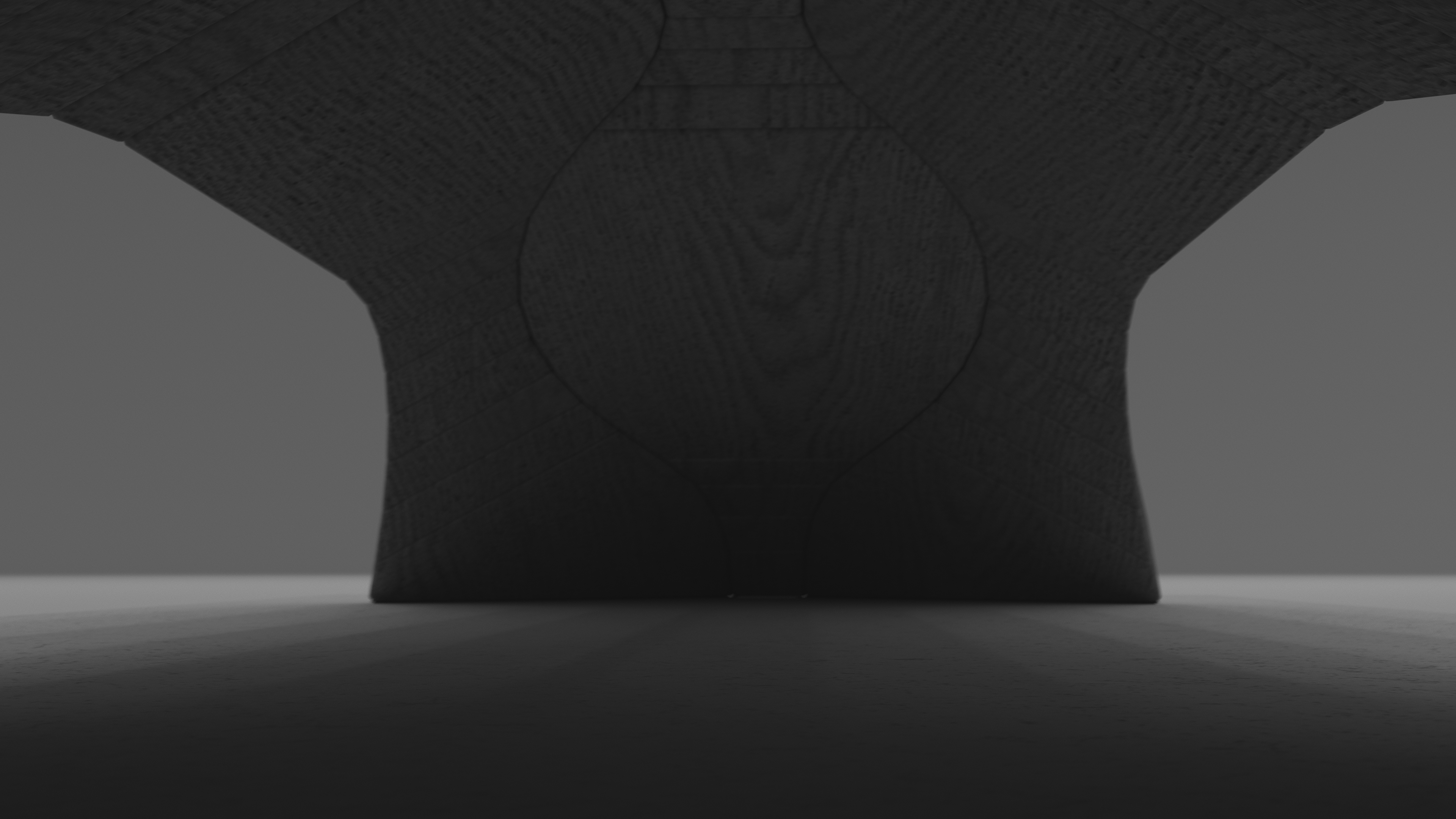

The form diagram generated from the force diagram is a funicular structure, more like a truss. However, in a real building structure, we will need to consider the relationship of the material thickness in the structure. By splitting the force diagram, the form of the structure can be altered so that the structure is layered, and then forces can be applied through the edges of the material.

Curve Funicular force/form diagram is generated by triangular subdivision. Those curvature are made by polyline which is divided by an arc. Shrinking/stretching the base pattern can form different variations.

Using a circle to divide the force diagram can generate a double-layer funicular structure which can be replaced by sheet-based material, and the force can be transferred through the material edge.

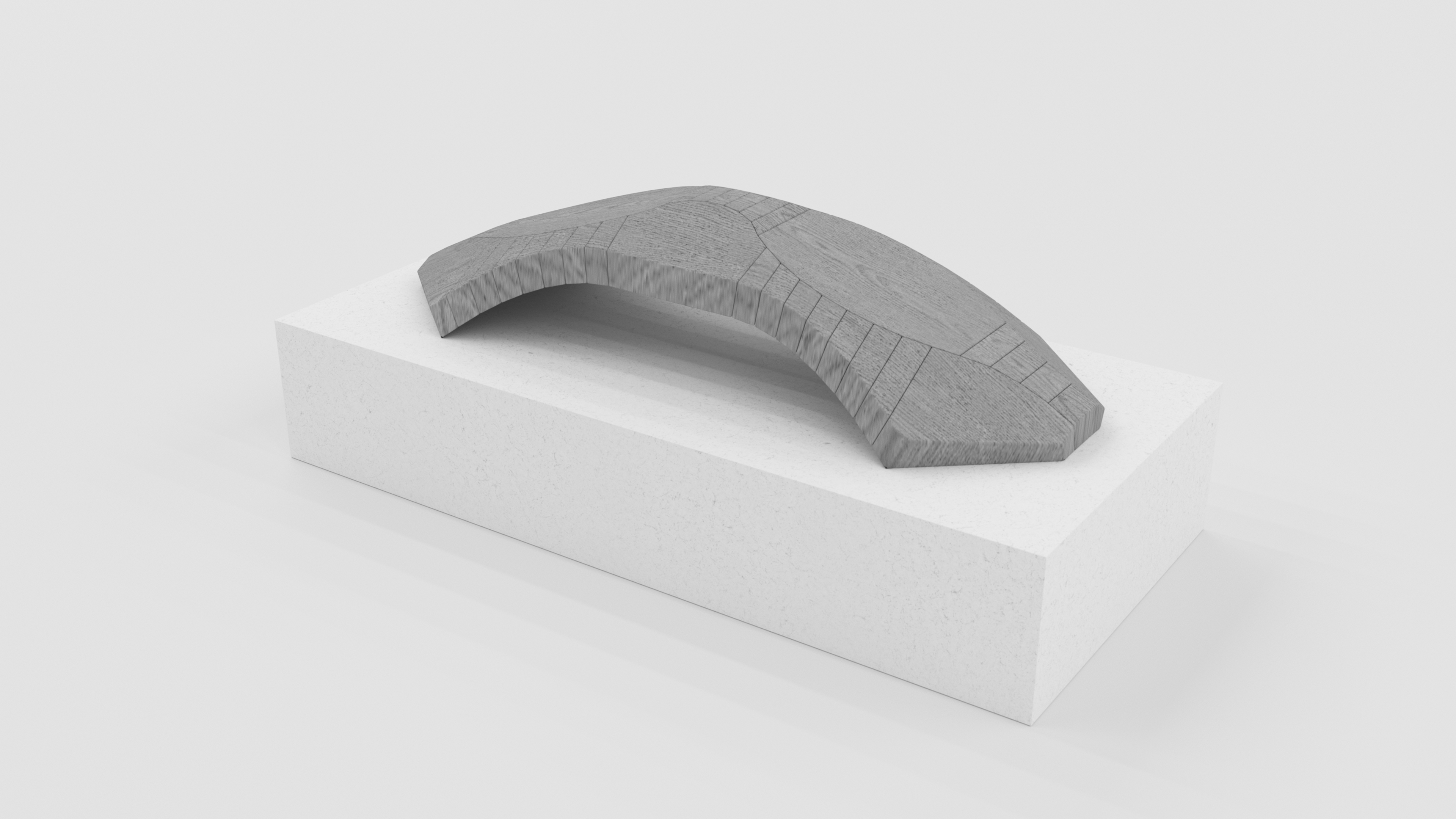

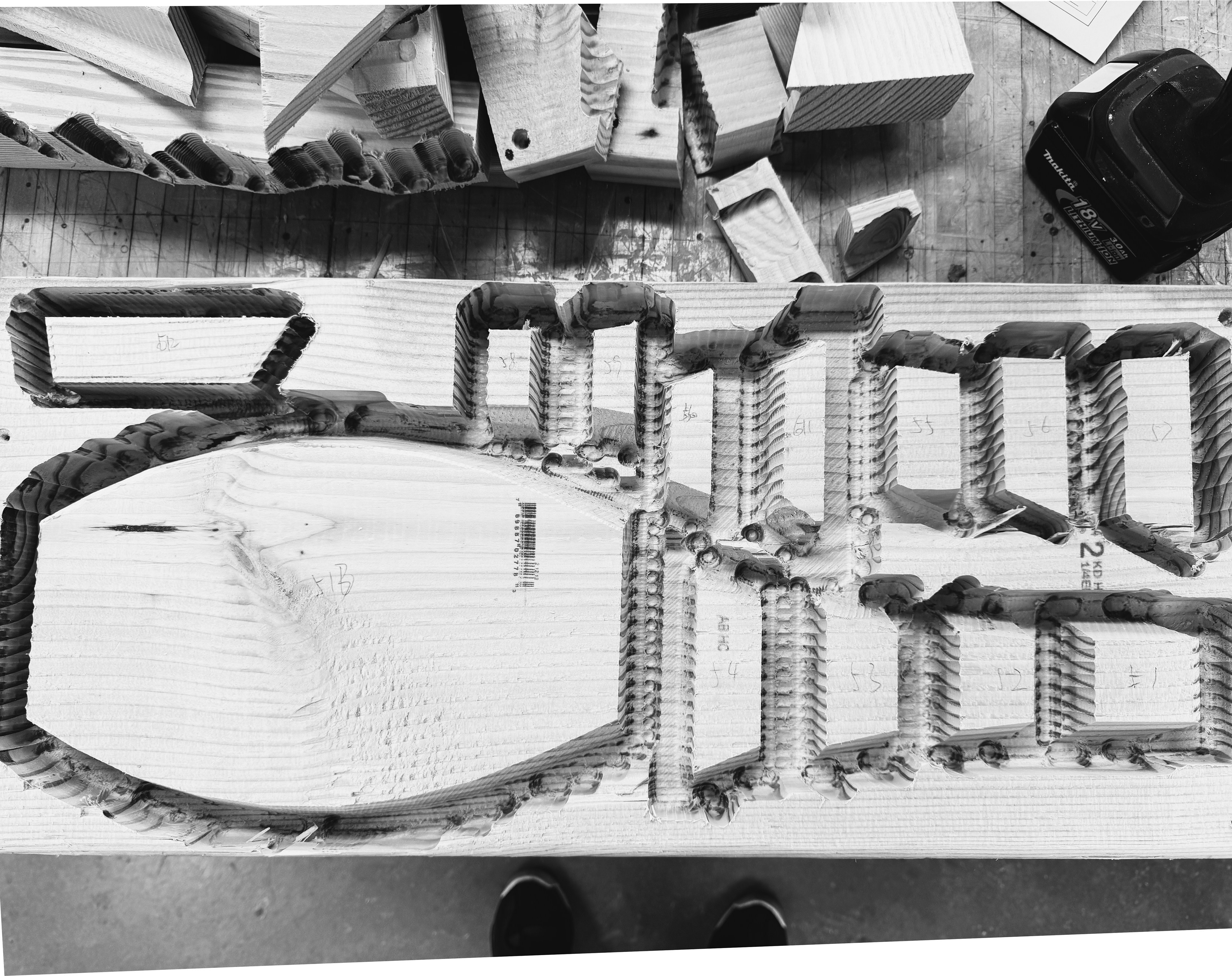

cnc milling

cnc milling

cnc milling

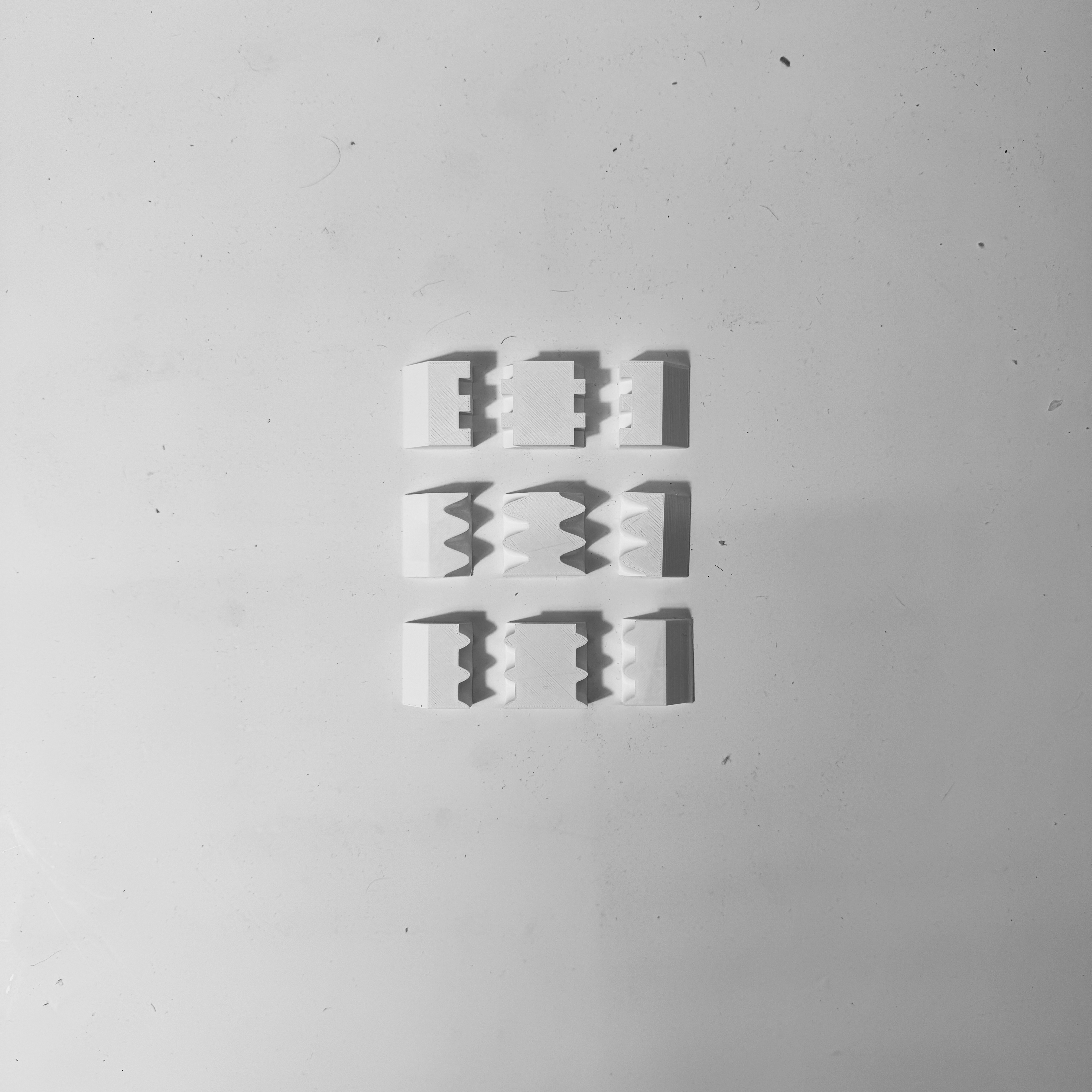

arrange components

arrange components